Composite Shiplap Exterior Siding A Complete Guide

Composite shiplap exterior siding offers a stylish and durable alternative to traditional wood siding. This guide dives into everything you need to know, from material choices and installation techniques to long-term maintenance and cost considerations. We’ll explore the various types of composite shiplap, their unique properties, and how they can transform the look of your home.

Whether you’re a seasoned DIYer or simply curious about upgrading your home’s exterior, understanding the advantages and drawbacks of composite shiplap is key to making an informed decision. We’ll cover everything from choosing the right material for your climate to tackling common installation challenges and ensuring your siding lasts for years to come.

Material Composition and Properties of Composite Shiplap Siding

Source: carolinacolortones.com

Composite shiplap siding offers a durable and attractive alternative to traditional wood siding. It combines the aesthetic appeal of wood with enhanced performance characteristics, making it a popular choice for homeowners. Let’s delve into the specifics of its composition and properties.

Material Composition of Composite Shiplap Siding

Composite shiplap siding is typically made from a blend of materials, most commonly a combination of PVC (polyvinyl chloride) and wood-plastic composites (WPCs). PVC-based siding is known for its exceptional durability and resistance to moisture, insects, and rot. WPCs, on the other hand, often incorporate recycled wood fibers, creating a more environmentally friendly option while still offering good strength and weather resistance. Some manufacturers also incorporate other additives to enhance specific properties, such as UV resistance or color stability.

Durability, Weather Resistance, and Maintenance of Composite Shiplap Siding

The durability and weather resistance of composite shiplap siding vary depending on the specific material composition. PVC siding generally boasts superior durability, exhibiting excellent resistance to impact, fading, and warping. WPC siding, while less resistant to impact than PVC, still offers significantly improved weather resistance compared to natural wood, minimizing the risk of rot, insect infestation, and water damage. Maintenance requirements are also generally lower for composite siding. Regular cleaning with soap and water is usually sufficient, eliminating the need for painting or staining every few years, unlike traditional wood siding.

Environmental Impact of Composite Shiplap Siding

The environmental impact of composite shiplap siding is a complex issue. While WPC siding often incorporates recycled materials, reducing the demand for virgin wood, the manufacturing process of both PVC and WPC siding can still have environmental consequences. The production of PVC involves the use of volatile organic compounds (VOCs), which can contribute to air pollution. However, the long lifespan and reduced maintenance needs of composite siding can offset some of these environmental impacts compared to the continuous replacement and maintenance required for wood siding. Furthermore, responsible sourcing of raw materials and efficient manufacturing processes are crucial factors to minimize the overall environmental footprint.

Comparison of Key Properties of Common Composite Shiplap Materials

The following table compares three common composite shiplap materials: PVC, WPC with high wood fiber content, and WPC with low wood fiber content. Note that specific properties can vary based on the manufacturer and exact formulation.

| Property | PVC | High Wood Fiber WPC | Low Wood Fiber WPC |

|---|---|---|---|

| Strength | High | Medium | High |

| Flexibility | Low | Medium-High | Medium |

| UV Resistance | Excellent | Good | Fair |

| Cost | High | Medium | Low-Medium |

Installation Methods and Techniques

Installing composite shiplap siding is a straightforward process, but achieving a professional look requires attention to detail and proper technique. This section is a step-by-step guide, including essential tools, safety measures, and best practices for a flawless installation. Remember to always consult the manufacturer’s instructions for your specific siding product, as variations may exist.

Proper installation ensures longevity, weather resistance, and the aesthetic appeal of your new siding. Taking your time and following these guidelines will minimize potential problems and yield a superior result.

Tools and Safety Precautions

Before starting, gather the necessary tools: measuring tape, level, speed square, circular saw or miter saw (with fine-tooth blade for clean cuts), hammer, nail gun (optional but recommended), safety glasses, work gloves, and a ladder (if needed for higher areas). Safety is paramount. Always wear safety glasses to protect your eyes from flying debris. Use work gloves to protect your hands, and ensure your ladder is stable and correctly positioned if working at heights. Follow all manufacturer’s safety guidelines for power tools.

Step-by-Step Installation Guide

- Prepare the Surface: Ensure the underlying wall is clean, dry, and free of any loose materials. Repair any damaged areas before installing the siding. This creates a solid base for the siding and prevents future issues.

- Install Starting Pieces: Begin at a corner or a pre-determined starting point. Use a level to ensure the first piece is perfectly aligned. Secure it with appropriate fasteners, following the manufacturer’s recommendations regarding spacing and penetration depth.

- Install Subsequent Pieces: Overlapping each piece according to the manufacturer’s specifications, continue installing the siding horizontally, maintaining consistent spacing and alignment. Use a level frequently to check for any vertical or horizontal misalignment. Proper overlap ensures watertightness.

- Cutting and Fitting: Use a fine-tooth blade to make precise cuts, minimizing splintering. For corners, accurately measure and cut pieces to fit snugly. Test-fit pieces before fastening to avoid mistakes. Accurate cuts create a professional, seamless finish.

- Fastening: Use the recommended fasteners and follow the manufacturer’s guidelines for spacing and penetration depth. Over-driving fasteners can damage the siding, while under-driving can compromise its security. Proper fastening is critical for longevity and weather resistance.

- Finishing: Install trim pieces around windows, doors, and corners, completing the installation. Caulk any gaps or seams to ensure a watertight seal. Appropriate caulking prevents water penetration and improves the overall aesthetic.

Achieving a Professional Finish

Consistent spacing and alignment are crucial for a professional look. Use a level and measuring tape frequently to ensure accuracy. Clean cuts made with a sharp blade will minimize splintering and create a neat finish. Consider using a miter saw for more accurate angled cuts, especially around corners and window frames. Take your time and pay attention to detail – rushing can lead to mistakes.

Common Installation Challenges and Solutions

Uneven walls can pose a challenge. Using shims to level the first few pieces can help compensate for irregularities. For severely uneven walls, consider furring strips to create a more level surface before installing the siding. Working with long lengths of siding can be cumbersome; consider using a helper to manage and position the pieces.

Troubleshooting Tips

- Uneven Gaps: Check your alignment frequently and use shims as needed to maintain consistent spacing.

- Splitted Cuts: Use a sharp, fine-tooth blade and a miter saw for angled cuts.

- Misaligned Pieces: Carefully check your alignment with a level before fastening each piece.

- Water Penetration: Ensure proper overlap and caulk all gaps and seams.

- Fastener Issues: Follow manufacturer’s recommendations for fastener type, spacing, and penetration depth.

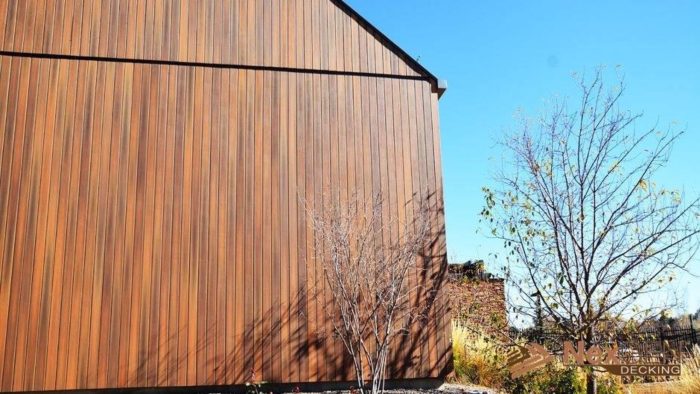

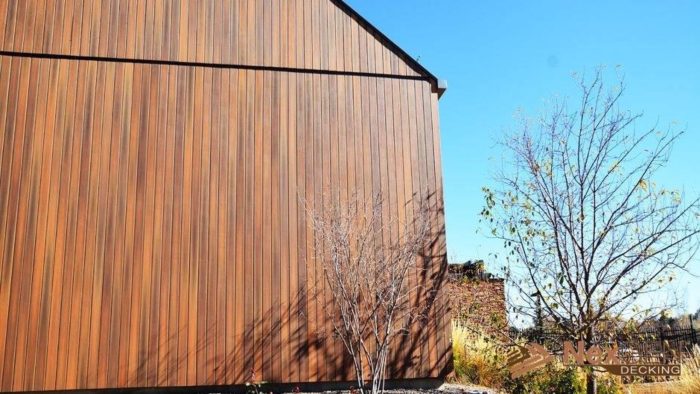

Design and Aesthetics: Composite Shiplap Exterior Siding

Source: prosuperiorconstruction.com

Composite shiplap siding offers a versatile and visually appealing exterior cladding option, adaptable to a wide range of architectural styles and personal preferences. Its clean lines and varied textural possibilities allow for both modern and traditional aesthetics. The choice of color and pattern significantly impacts the overall look and feel of a home.

Design Applications Across House Styles

Composite shiplap siding seamlessly integrates into diverse architectural styles. On a farmhouse, the siding’s rustic charm is enhanced by choosing a warm, natural color palette like creamy whites, soft greys, or muted browns. The horizontal orientation of the shiplap further accentuates the farmhouse aesthetic. In contrast, a modern home benefits from the clean lines of shiplap, especially when paired with a bold, monochromatic color scheme—think deep charcoal grays, crisp whites, or even striking blacks. Vertical shiplap installation can add a sleek, contemporary feel. Traditional homes can embrace the classic elegance of shiplap with a more subdued color palette, such as muted greens, blues, or earth tones, often employing horizontal installation for a timeless appeal.

Visual Impact of Colors and Textures

The color and texture of composite shiplap siding profoundly influence the home’s overall visual impact. A wide array of colors are available, from classic neutrals to vibrant hues. Neutral palettes, including various shades of white, beige, gray, and taupe, create a timeless and versatile look, complementing many landscaping styles. Earthy tones, such as browns, greens, and creams, evoke a natural, rustic feel, ideal for homes nestled in wooded areas or those aiming for a more organic aesthetic. Bold colors, like deep blues, reds, or greens, make a statement, adding a vibrant pop to the home’s exterior. Textures also play a crucial role. Smooth shiplap offers a clean, modern look, while textured options, mimicking the look of wood grain or even stone, add depth and visual interest. A slightly rougher texture can soften the appearance of a home, creating a more welcoming and less stark feel.

Shiplap Patterns and Their Visual Effect

The arrangement of shiplap—vertical, horizontal, or a combination of both—significantly impacts the perceived proportions and style of a home.

| Pattern | Visual Effect | Suitable Architectural Styles | Example Color Palette |

|---|---|---|---|

| Horizontal Shiplap | Creates a sense of width and spaciousness, emphasizes traditional aesthetics. | Farmhouse, Traditional, Ranch | Warm whites, soft greys, muted browns |

| Vertical Shiplap | Adds height and a modern, sleek feel, draws the eye upward. | Modern, Contemporary, Craftsman | Deep grays, charcoal, crisp whites |

| Mixed Shiplap (Horizontal & Vertical) | Provides visual interest and can be used to highlight architectural details. | Modern Farmhouse, Eclectic | Two-tone scheme (e.g., dark gray vertical, light gray horizontal) |

| Stacked Shiplap (Narrow boards) | Creates a more refined, detailed appearance. | Modern, Craftsman | Clean whites, muted blues |

Aesthetic Comparison to Other Cladding Options

Compared to other exterior cladding options, composite shiplap offers a unique blend of aesthetics and practicality. Vinyl siding, while affordable and low-maintenance, often lacks the visual richness and texture of shiplap. Brick and stone offer durability and a classic look, but they can be significantly more expensive and heavier than composite shiplap. Composite shiplap provides a happy medium, offering the aesthetic appeal of wood without the high maintenance and susceptibility to damage. It allows for a wider range of design choices in terms of color, texture, and pattern, offering a customizable and visually stunning exterior.

Cost and Lifespan Considerations

Choosing exterior siding involves a careful balancing act between upfront costs and long-term value. Composite shiplap offers a compelling option, but understanding its price range and longevity is crucial for making an informed decision. This section will break down the cost factors and explore the lifespan of this popular siding material.

The cost of composite shiplap siding varies significantly depending on several key factors. Material costs themselves range widely, influenced by the specific manufacturer, the type of composite material used (e.g., wood-plastic composite, PVC), and the desired aesthetic features like texture and color. Installation expenses are also a major component, fluctuating with regional labor rates, project complexity (e.g., intricate designs, extensive trim work), and the size of the area being sided.

Cost Breakdown of Composite Shiplap Siding

A realistic budget for composite shiplap siding should encompass both material and labor costs. Material costs typically range from $5 to $20 per square foot, depending on the factors mentioned above. High-end, specialized composites with premium finishes can reach the higher end of this spectrum. Installation labor usually adds another $3 to $10 per square foot, again varying by location and project specifics. For a 1,000 square foot house, this could mean a total cost ranging from $8,000 to $30,000 or more. Always get multiple quotes from reputable contractors to compare prices and ensure a fair assessment.

Factors Influencing Overall Cost

Several factors can significantly impact the final cost of your composite shiplap project. These factors are interconnected and should be considered collectively.

- Material Type: Higher-quality composites, those with enhanced durability and weather resistance, generally command higher prices.

- Labor Rates: Labor costs vary widely by geographic location. Areas with high demand for skilled labor will typically have higher installation costs.

- Project Size: Larger projects naturally involve more material and labor, leading to increased overall costs. Conversely, smaller projects may benefit from economies of scale in material purchasing.

- Complexity of Installation: Intricate designs, extensive trim work, or difficult-to-access areas will increase installation time and cost.

- Permitting and Inspections: Local regulations may require permits and inspections, adding to the overall project expense.

Lifespan and Durability of Composite Shiplap Siding, Composite shiplap exterior siding

Composite shiplap siding is known for its exceptional durability and longevity. Under normal conditions, it can last for 30-50 years or even longer, significantly outlasting many other siding options like wood or aluminum. However, environmental conditions can affect this lifespan.

Long-Term Cost-Effectiveness Compared to Other Materials

While the initial cost of composite shiplap siding might be higher than some alternatives like vinyl or aluminum, its longer lifespan and lower maintenance needs often make it a more cost-effective choice in the long run. Wood siding, for instance, requires regular painting or staining, and is susceptible to rot and insect damage, leading to higher maintenance and replacement costs over time. A life-cycle cost analysis, considering initial investment, maintenance, and replacement costs over the material’s lifespan, usually favors composite shiplap siding in many cases. For example, a homeowner might spend $20,000 on composite shiplap with minimal maintenance over 50 years, while wood siding might require $10,000 initially and $15,000 in maintenance and repairs over the same period, making the composite a more financially sound investment.

Maintenance and Repair

Source: newtechwood.com

Composite shiplap siding, while durable, still requires regular maintenance to ensure its longevity and attractive appearance. Neglecting maintenance can lead to premature wear and tear, impacting both the aesthetics and the structural integrity of your home’s exterior. A proactive approach to upkeep will save you money and headaches in the long run.

Regular maintenance involves a combination of cleaning and inspection to catch minor problems before they escalate. This preventative approach minimizes the need for extensive repairs and ensures your siding retains its beauty for years to come. Remember that different composite materials may require slightly different care instructions, so always refer to the manufacturer’s recommendations for your specific product.

Regular Maintenance Schedule

A simple schedule can help you stay on top of maintenance tasks. Consider the following as a guideline, adjusting based on your climate and environmental conditions.

- Annual Inspection: A thorough visual inspection should be performed annually to check for any signs of damage, such as cracks, dents, loose panels, or fading. Pay close attention to areas most exposed to the elements.

- Semi-Annual Cleaning: Clean your siding at least twice a year, in spring and fall. This removes dirt, grime, and pollen, preventing buildup and potential damage.

- Immediate Repairs: Address any minor damage, such as scratches or loose panels, as soon as possible. Ignoring small problems can allow them to worsen, leading to more extensive and costly repairs.

Repairing Common Issues

Scratches, dents, and fading are common issues with exterior siding. Fortunately, many can be addressed with relatively simple repairs.

- Scratches: Minor scratches can often be buffed out using a soft cloth and a mild detergent. For deeper scratches, you might need a specialized composite repair kit, which often includes fillers and paints to match your siding’s color. These kits are widely available at home improvement stores.

- Dents: Small dents may be able to be carefully pushed back into shape using a gentle, blunt object. For more significant dents, replacement panels might be necessary.

- Fading: Fading is often caused by prolonged sun exposure. While you can’t completely reverse fading, you can restore some of the color using a composite siding cleaner and restorer. These products are specifically formulated to clean and revitalize the color of composite materials without damaging the surface. Always test any cleaning product in an inconspicuous area first.

Replacement Parts and Panels

Replacement parts and panels are readily available from most manufacturers and home improvement stores. The cost varies depending on the brand, size, and color of the panels. Expect to pay more for specialty colors or textures. It’s advisable to keep a few extra panels on hand in case of unforeseen damage, especially if your siding is a discontinued color.

Cleaning and Restoring Faded Siding

Restoring faded composite shiplap siding involves a multi-step process. First, thoroughly clean the siding using a pressure washer set to a low pressure setting. Next, apply a composite siding cleaner specifically designed for your siding type. Follow the manufacturer’s instructions carefully. Finally, apply a composite siding restorer to help revitalize the color. Again, always test any product in an inconspicuous area before applying it to the entire surface. Remember that complete color restoration might not be possible, but you should see a noticeable improvement. For severely faded areas, replacement panels may be the most effective solution.

Closure

Source: com.au

From its attractive aesthetic to its low-maintenance nature, composite shiplap exterior siding presents a compelling option for homeowners seeking a durable and beautiful upgrade. By carefully considering the material type, installation process, and long-term maintenance, you can enjoy the benefits of this modern siding solution for years to come. Remember to weigh the initial cost against the potential for long-term savings and reduced maintenance needs. Ultimately, the right choice depends on your individual needs and preferences.

Key Questions Answered

Is composite shiplap siding fire-resistant?

Many composite shiplap options offer improved fire resistance compared to wood, but the level of fire resistance varies depending on the specific material and its composition. Check the manufacturer’s specifications for fire ratings.

Can I paint composite shiplap siding?

Yes, but it’s important to choose a paint specifically designed for exterior use on composite materials. Always test the paint in an inconspicuous area first to ensure compatibility and color consistency.

How do I clean composite shiplap siding?

Regular cleaning with a mild detergent and water is usually sufficient. For tougher stains, you may need a pressure washer, but be careful not to damage the siding with excessive pressure.

Does composite shiplap siding fade over time?

Some fading can occur, especially with prolonged sun exposure. Choosing a high-quality composite with good UV resistance will minimize this issue. Regular cleaning can also help maintain the color.

What is the warranty on composite shiplap siding?

Warranties vary significantly between manufacturers and product lines. Check the manufacturer’s warranty information for details on coverage and duration.

Comments are closed.